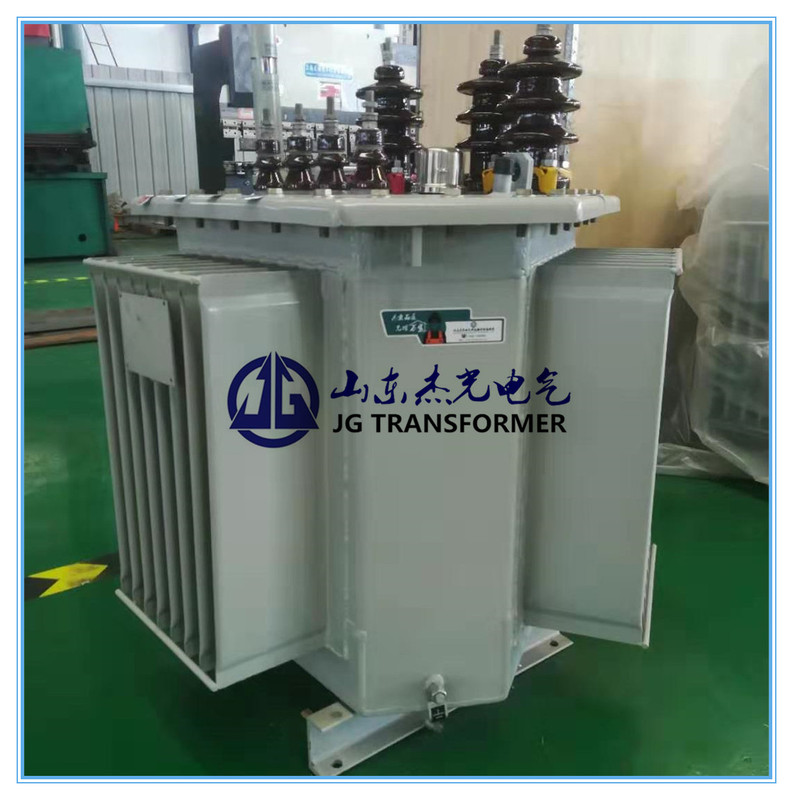

S13-M-RL Three-Dimension Iron Core Transformer

S13-M-RL Three-Dimension Iron Core Transformer

S13-M-RL Three-Dimension Iron Core Transformer

- Product Details

- Parameters

Implement Criterion

1.IEC 60076-1:2011

2.IEC 60076-2:2011

3.IEC 60076-3:2013

4.IEC 60076-5:2006

5.IEC 60076-10:2016

Working Conditions

1.Altitude: ≤1000m

2.Temperature: ≤40℃

3.Maximum wind speed: 35m/s

4.Maximum relative humidity: 90%

5.Earthquakes: horizontal acceleration: 3m/s2; vertical acceleration: 1.5m/s2

6.Pollution Grade: Grade III

7.Continental or marine climate

Product Description

Construction Advantages

1、Energy saving and noise reduction

2、Three-phase magnetic circuit balance

3、Strong Short Circuit Resistance

4、Small area and beautiful appearance

Winding

Low-voltage coil is single-layer or multi-layer cylindrical structure, which is made of paper-wrapped oxygen-free copper flat wire or copper foil. High-voltage coil is made of multi-layer cylindrical structure and polyester enamelled copper wire or paper-wrapped copper wire. It has the characteristics of good mechanical strength and short-circuit resistance. Interlayer insulation adopts DLZ-0.08 insulating point glue paper. After winding, the phase can be dried through the body of the coil. The two adjacent layers are firmly bonded, which enhances the mechanical strength of the coil.

Iron core:

The core is a rolled iron core. There is no gap and seamless in the core magnetic circuit. The magnetic conduction direction of the silicon steel sheet is the same as that of the magnetic circuit, which reduces the noise generated by the transformer when it is running. Compared with the three-dimensional coil core transformer, the three-phase magnetic circuit has the same length and the shortest length, making the phase magnetic circuit balanced and the noise lower. It is a new type of energy-saving and environmental protection electrical equipment.

Oil tank:

Generally rectangular structure, according to the size of the capacity, the steel plate of the box body is made of 4 mm, 5 mm and 6 mm steel plates with different thickness to ensure that the tank does not deform during long-distance transportation; the heat dissipation part is made of 1.2 mm or 1.5 mm steel plate with expansion performance, which not only ensures the heat dissipation of the transformer while running, but also ensures the thermal expansion and cold contraction of the transformer oil, and is not easy to produce leakage. Phenomenon.

Connection Groups and Voltage Range:

Generally, the connection group is D, yn11, and the tapping range is (+5%), (+2x2.5%) or (+4x2.5%) of rated voltage.